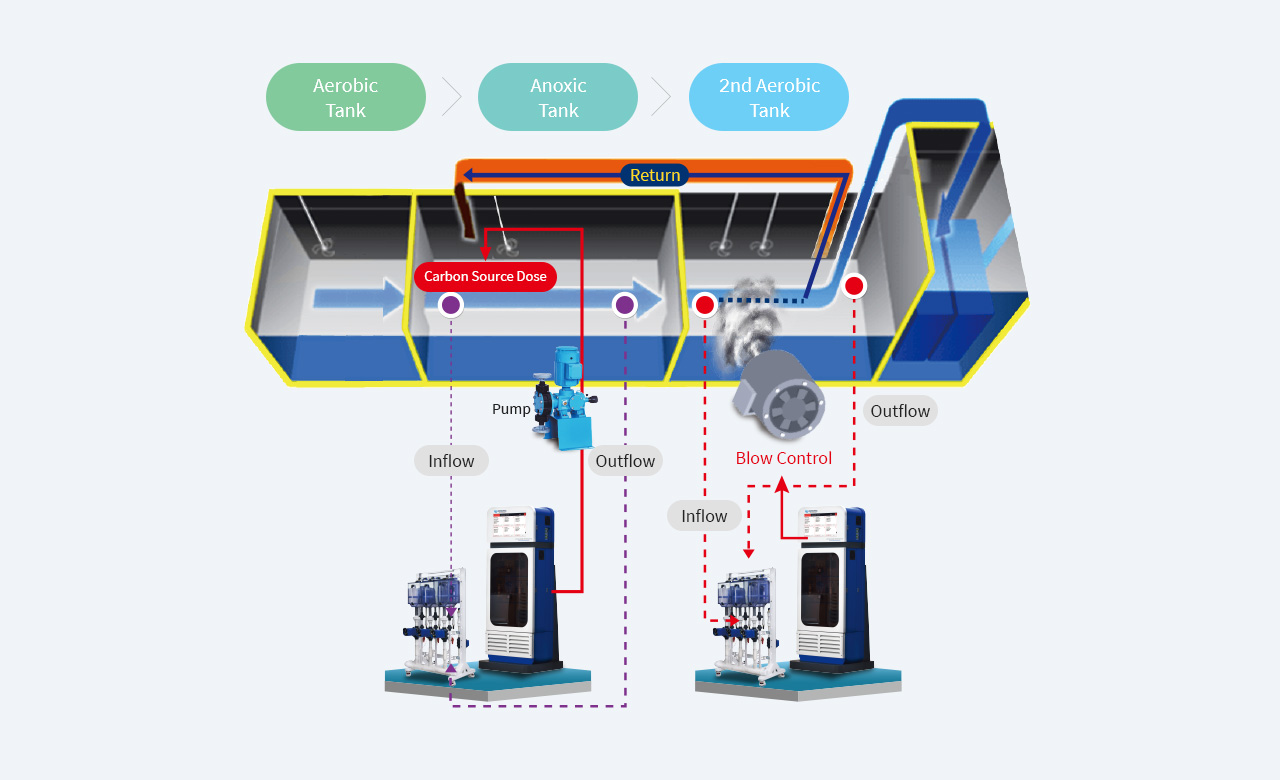

Process Control

Bio Reactor

The bioreactor consists of an anaerobic tank, anoxic tank, aerobic tank, etc. WEKO-AiO-WQMS can be used for denitrification by controlling the input of carbon source in the anoxic tank, and for controlling air volume in the aerobic tank.

- ANOXIC TANK – – Increasing Denitrification Efficiency by Controling Carbon Source

-

- Multi Sampling/Filtering Machine : Filtering and sampling the anoxic inlet and outlet water to generate measurement samples

- WEKO-AiO-WQMS : Real-time measurement of nitrogen concentration and removal status, carbon source requirement and control of carbon source input in anoxic tank

- Increasing energy efficiency by reducing carbon source usage.

- Monitoring dissolved oxygen or pH that affecting denitrification

- 2nd AEROBIC Tank – Energy Saving by Controlling Air Volume

-

- The aerobic tank is a section in which micro-organism grow and organic oxidation and nitrification are performed by using oxygen.

- Multi-Sampling/Filtering Machine : Filtering and Sampling the aerobic inlet and outlet water to generate measurement samples

- WEKO-AiO-WQMS : Measurement of NH3-N concentration in aerobic tank, calculation of appropriate oxygen input amount and blower control for oxygen input

- Energy Saving by increasing blower control efficiency

- Supporting data measurement about various elements affected by air volume in the aerobic tank